PRODUCT HIGHLIGHTS

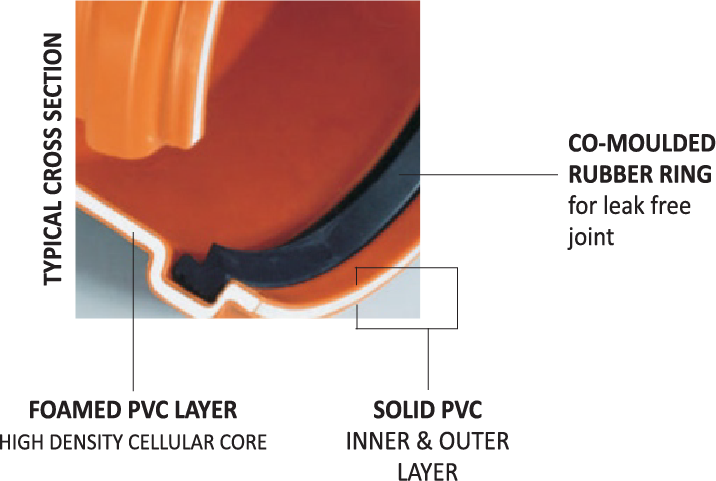

- Triple layer Foamcore technology

- Available in Pushfit & Selfit jointing technology

- Smooth finish and rodent resistant

- Pipes manufactured as per IS 16098 (Part 1) : 2013

- Fittings manufactured as per EN 1401-1:2009 (SDR 41) standard

Easy to Install

High Durability

Leak Proof

Highly Flexible

Lightweight

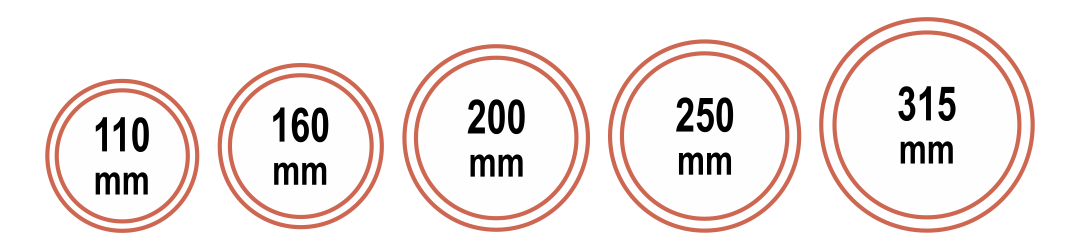

Size Availability

The Foamcore Advantage

Foamcore pipes are multilayer pipes having outer and inner layers of PVC and middle layer with foamed PVC. Outer and inner layers are designed to take the load and middle layer of foamed PVC ensures retention of shape of the pipe under external load. The typical construction of these pipes make it a lightweight pipe.

TRUFLO Foamcore pipes are easy to install. They are available in ringfit and selfit options. This jointing system is amply strong for the non-pressure application of underground system. The joints are completely watertight & reduce the possibility of ingress or seepage of water assuring best hygiene standard.

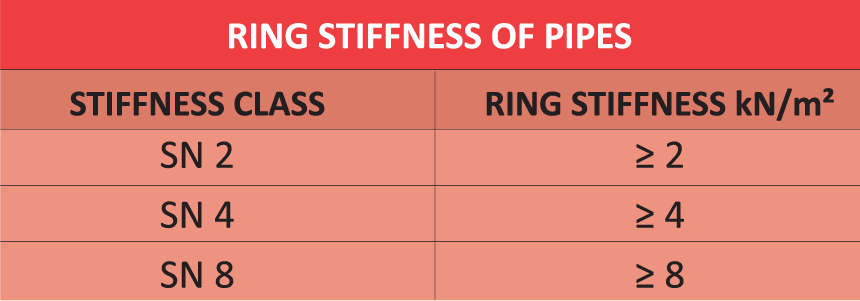

Ring Stiffness

The ring stiffness of the pipe determines the ability to resist soil loads, external hydrostatic pressure, negative internal pressures and traffic loads. Nominal ring stiffness is expressed as kN/m².

TRUFLO foamcore pipes are manufactured as per IS 16098 (Part 1) : 2013, with a constant minimum stiffness as either designated as SN2, SN4 and SN8.

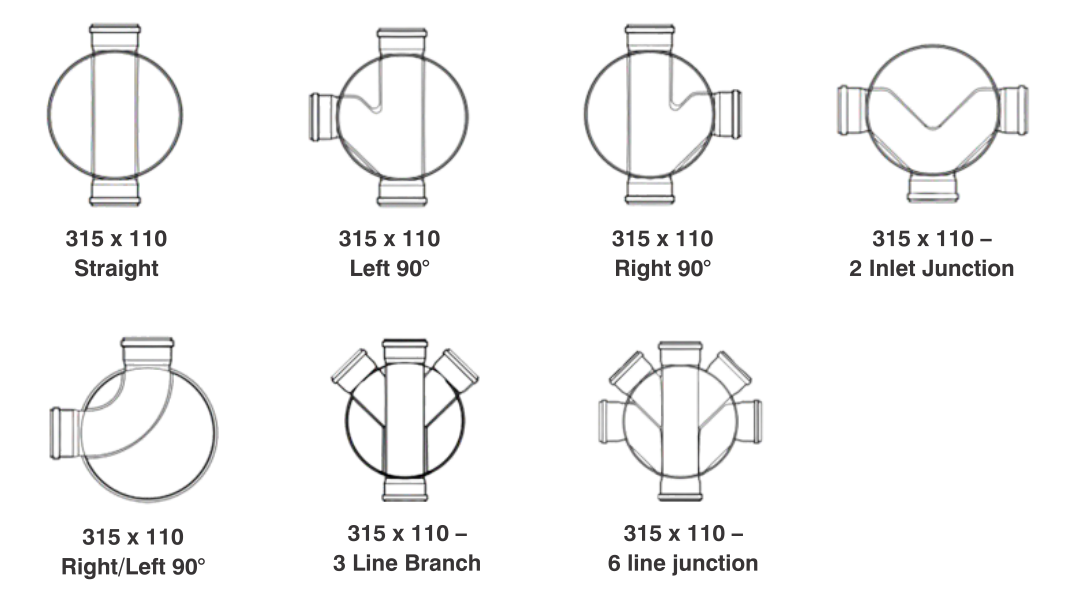

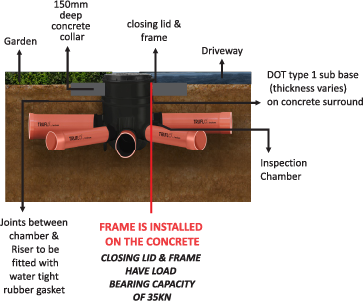

Inspection Chambers

Inspection chambers provide easy access to the sewage line for cleaning and maintenance purposes. Inspection chambers are used in following scenarios:

- There are too many long sewage segments

- At the converging inlets

- Change of direction

- For new connections

- To disconnect public and private sewer lines and at places of sewage fall.

Size of an Inspection Chamber

Inspection chambers are available in manhole diameter of 315mm & various configurations of pipe slots of 110 mm. The height of the inspection chamber can be increased using height riser as per site requirements.

Components

Installation

Configurations