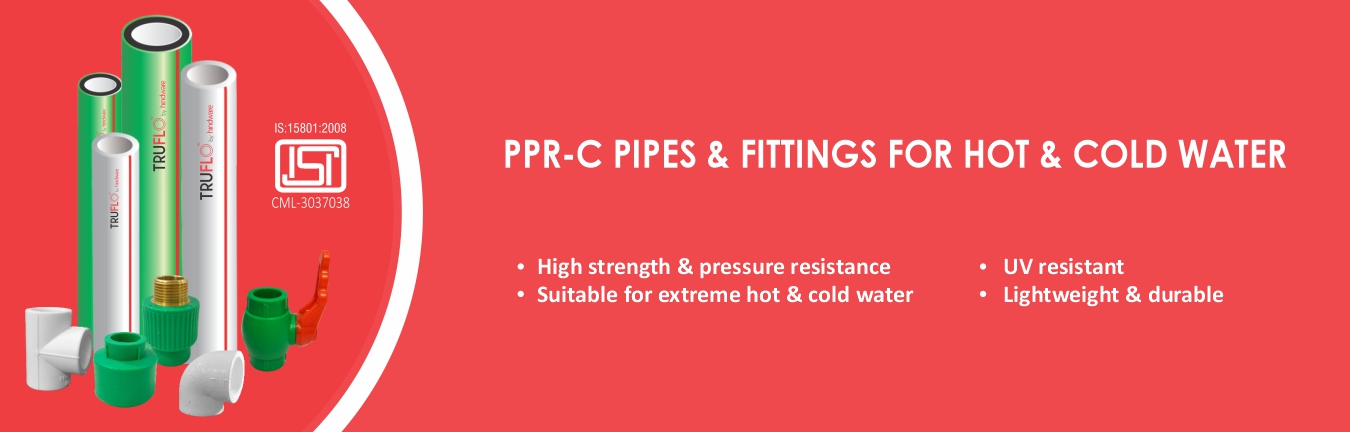

The PPR-C Advantage

PPR-C stands for "Polypropylene Random Copolymer", which is the key to the exceptional performance of TRUFLO PPR-C pipes. These are a winning combination of high temperature resistance, corrosion resistance, durability, and lightweight design. This combination makes them a go-to choice for applications like:

- Residential, commercial, and industrial plumbing systems for extreme hot and cold water distribution

- Heating systems including radiator connections, underfloor heating, and district heating

- Industrial piping systems for various applications like chemical processing, food & beverage, and pharmaceutical industries

- Water treatment plants

PRODUCT HIGHLIGHTS

- Ideal for extreme Hot & Cold Water Application.

- Suitable for High Pressure Lines.

- Withstands temperature range from -10°C to 95°C.

- Low Thermal Conductivity 0.24 W/mK.

- Hygienic & Low Bacterial Growth.

- Smooth Internal surface - no frictional losses

- Anti Corrosive & Chemical Resistance.

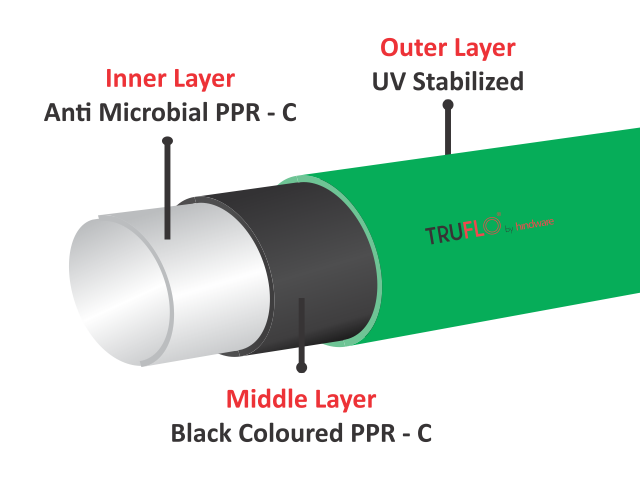

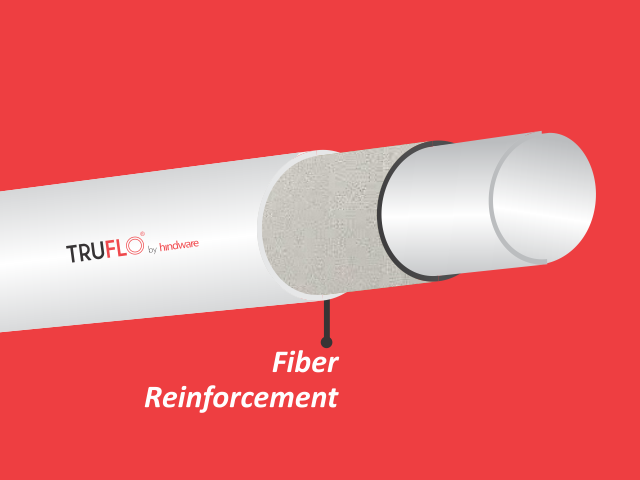

TRUFLO Trutherm PPR-C Edge

For the discerning consumers and applications demanding higher efficiency and enhanced functionality Truflo's Trutherm PPR-C pipes are ideal choice. These pipes are designed with high enduring fiber reinforcement and UV resistance. The middle layer is mechanically stabilized with a fibertherm mix, while the outer layer is UV-resistant. The inner layer is made of PPR food-grade material.

ADVANTAGES

- 4x lower linear thermal expansion.

- 25% higher pressure capacity than normal PPR-C pipes.

- 25% increased flow rate.

- 20% reduced passive heat loss for non-insulated pipes.

*Available Sizes: 20mm, 25mm, 32mm, 40mm, 50mm

| Green Triple Layer | White Mono Layer | White Triple Layer TRUtherm |

|---|---|---|

| 20mm (1/2") to 50mm (2") | 20mm (1/2") to 50mm (2") | 20mm (1/2") to 50mm (2") |

| PN 16 & PN 20 | PN 16 & PN 20 | PN 20 |

Working Pressure

| TEMP. | SERVICE LIFE | PIPE SERIES | ||

|---|---|---|---|---|

| SDR 11 PN-IO | SDR 7.4 PN-16 | SDR6 PN-20 | ||

| 0° C | Yrs. | ALLOWABLE WORKING PRESSURE | ||

| 10° C | 50 | 8.2 | 28.8 | 36.3 |

100 | 17.7 | 28.1 | 35.4 | |

| 20° C | 50 | 15.5 | 24.5 |

30.9 |

100 | 15 | 23.8 | 29.9 | |

| 30° C | 50 | 13.1 | 20.7 |

26.1 |

100 | 12.8 | 20.2 | 25.5 | |

| 40° C | 50 | 11 | 17.5 |

22 |

100 | 10.7 | 16.9 | 21.3 | |

| 50° C | 50 | 9.3 | 14.7 |

18.5 |

100 | 8.9 | 14.2 | 17.8 | |

| 60° C | 25 | 8 | 12.6 |

15.9 |

50 | 7.7 | 12.1 | 15.3 | |

| 70° C | 25 | 6.1 | 9.6 | 12.1 |

50 | 5.1 | 8.1 | 10.2 | |

| 80° C | 10 | 4.8 | 7.6 |

9.6 |

25 | 3.8 | 6.1 | 7.6 | |

| 90° C | 5 | 3 | 4.8 |

6.1 |

10 | 2.6 | 4 | 5.1 | |

3 STEP INSTALLATION

-

Cut & Clean

Measure and cut the pipe at right angle using PPR pipe cuer & clean the burr with fine cloth before heating.

-

Heat

Attach the dies, to the heating panel of welding machine, according to the size of the pipes and fittings to be welded. Set the machine temp to 260° C. Insert the pipe & fitting into the respective die sockets and heat both components.

-

Weld

Post heating, immediately insert pipe into the fitting by applying light pressure and hold for few seconds for leak-proof welded joint.